|

|

Post by Oldtimer on Sept 24, 2020 8:21:24 GMT -8

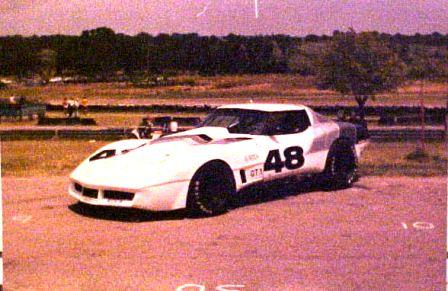

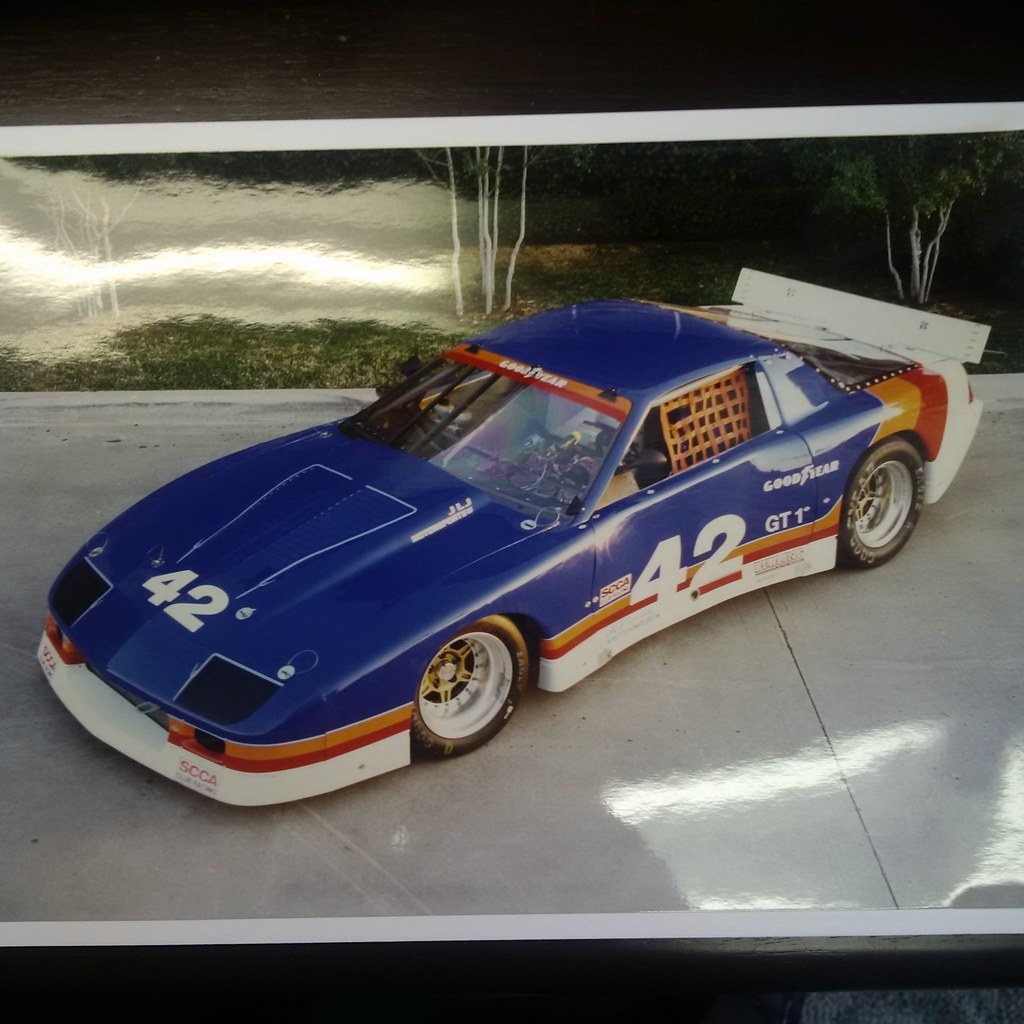

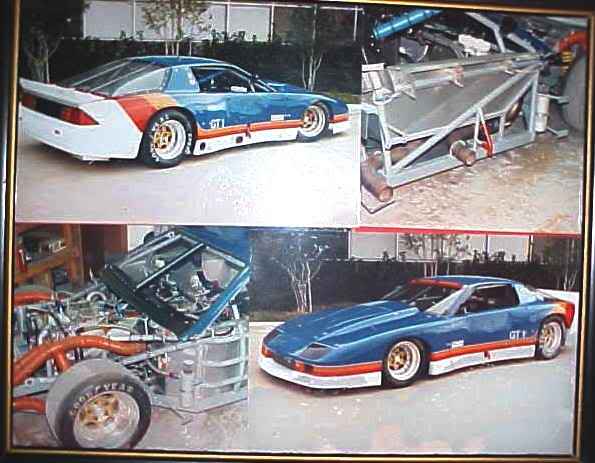

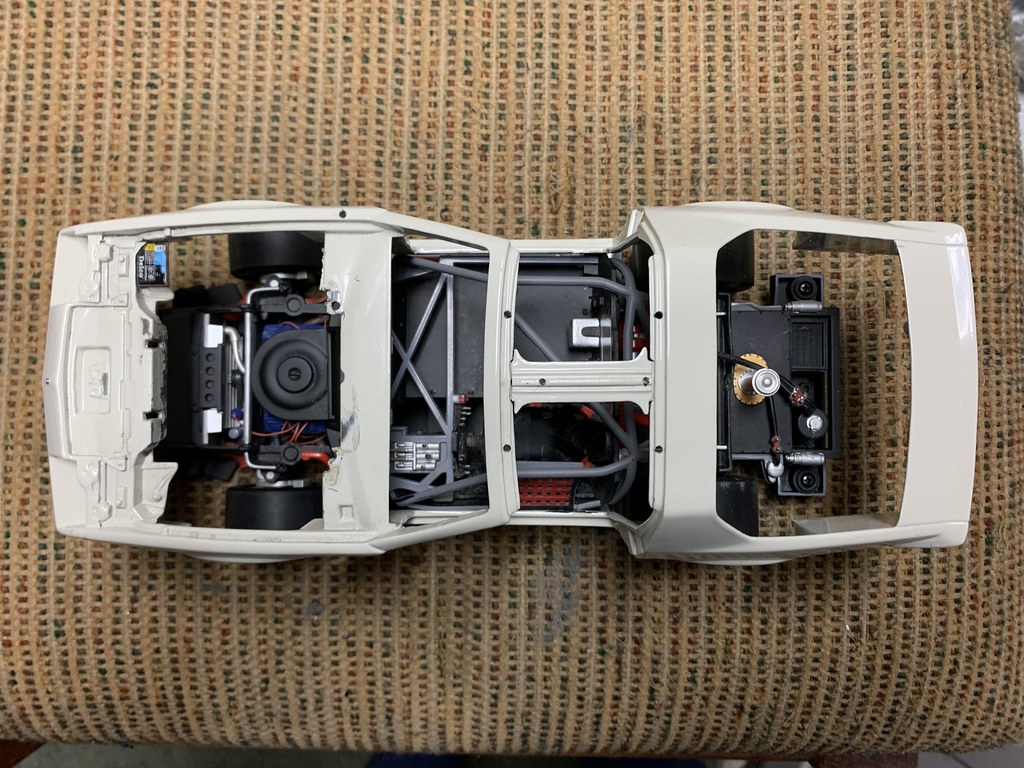

Around 1986, my race car partner and I were wanting to upgrade our C3-chassied/'82 Pickett-bodied Corvette for something a little newer.  We had been in constant contact with the prior owner of the Corvette (who produced fibreglass race car bodies), and when we mentioned to him that we wanted to upgrade, he informed us that he had acquired a tube frame chassis for a 3rd Generation Camaro in order to test fit bodies to, and that he was done with it. Jake and I drove to Milwaukee from Dallas, TX with the rolling chassis of our Corvette in our trailer, and drove back with, essentially, a new car in kit form. The tube frame Camaro chassis had the rollcage, and front and rear clips attached, but that was it. The rest of the car parts, suspension, rear end, fuel cell, brakes, etc. were in boxes. Along with a couple of volunteers, and through some troubling personal and economic times, we persevered and produced our Camaro.    We fabricated almost everything you can see in these pictures, including hanging the body (the seller had merely mocked up his body panels with tack welded brackets and racer's tape), completing the aluminum interior (firewall, cockpit, exhaust tunnel), completing all the plumbing (dry sump oil system, brakes, fuel lines, and engine cooling), completing all the wiring, and detailing and finishing. I have been wanting to try to create a duplicate, so will be chronicling that effort here. My donors will be a SunStar 1982 Camaro Z28, and a GMP 1996 Trans Am Camaro.   I'll skip the boring disassembly process and go right to the staging of the two donor components.  Here you can see from above that the componentry will be a nice fit.  Here from the side you can see that there are already some conflicts which don't allow the body to seat onto the chassis.  Going to be some major Dremel work. Stay Tuned! |

|

|

|

Post by arcticwolf on Sept 24, 2020 8:43:54 GMT -8

I'm lovin it Jim.

|

|

|

|

Post by tatocorvette on Sept 24, 2020 10:50:51 GMT -8

This is really cool! Both the project and the story behind it!

|

|

|

|

Post by Oldtimer on Sept 24, 2020 16:14:44 GMT -8

My goal is to retain the integrity of the GMP chassis. They are nicely detailed and becoming more difficult to acquire at a reasonable price. My donor was actually a previously displayed, no box model, that also had some issues with the paint.  The first issue to deal with on the body will be these "ledges" which stick inward from the skin of the Camaro body, and interfere with the rollcage of the chassis. They don't really serve any purpose.  Next, I will probably totally remove the section between the two A-pillars of the body. There is good detail in this area on the GMP chassis, which I want to have exposed. Plus the windshield of the SunStar Camaro should blend nicely and close any gaps.    Finally, all the detail at the nose of the donor body is not necessary, as with our fibreglass replica bodies, these were simply an aerodynamic skin over the functional parts of the racer. Additionally, the GMP chassis is also well detailed in this area, and any gaps, as we did on the real racer, can be filled with aluminum (styrene) sheet.   Going fire up the Dremel tool today (got five batteries for the bigger one, two for the smaller). Hopefully we'll have some progress shots tonight or tomorrow. |

|

|

|

Post by Oldtimer on Sept 25, 2020 13:13:59 GMT -8

So, several hours, battery recharges, and cutting blades later, here's where we are, and I was afraid of this. Sides have been clearanced.  Areas below the A-pillars have been cleaned up after the piece connecting the A-pillars was removed.  Area around the nose has been cleaned up, and lots of detail of the GMP chassis are visible.  But Houston, we have a problem.  I was hoping to not have to make any significant changes to the GMP chassis, however these stalks are keeping the body from dropping into place.  Going to sleep on it. |

|

|

|

Post by Joel_W on Sept 26, 2020 6:20:39 GMT -8

Jim,

Just a great project to follow. So far I'd say that you're making fantastic progress. Looking forward to your next update.

Joel

|

|

|

|

Post by Oldtimer on Sept 28, 2020 8:38:10 GMT -8

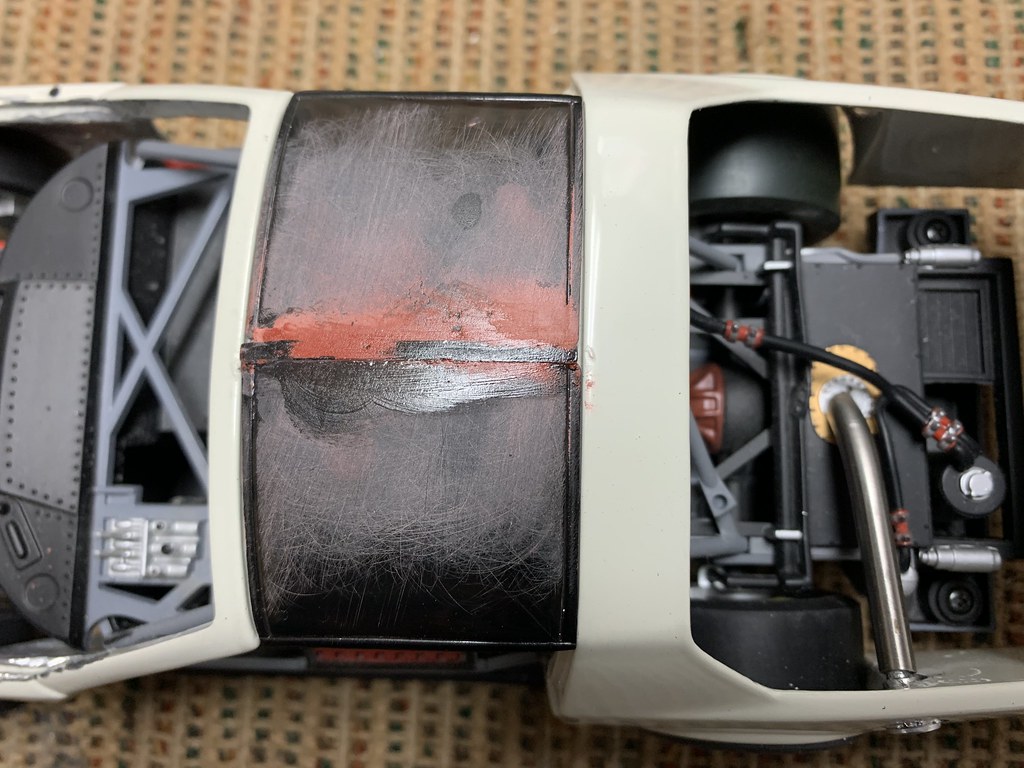

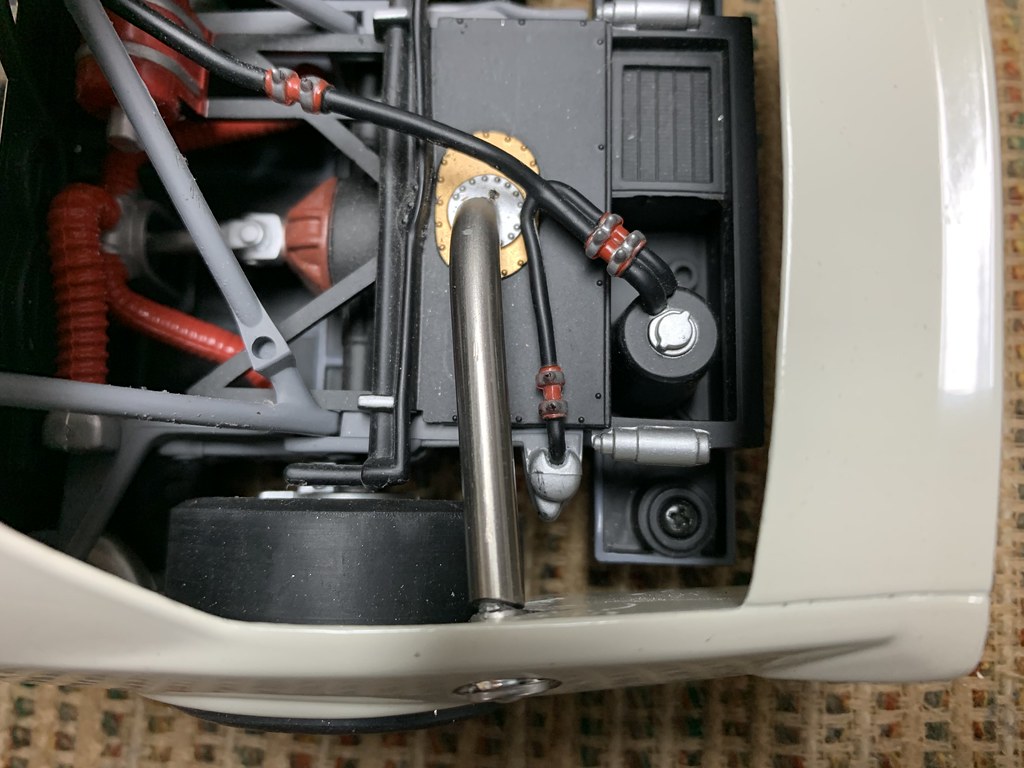

So, with a weekend behind us, and a lot of zinc dust and pieces littering my workbench and workshop floor, considerable progress has emerged. I bit the bullet, and cut off the plastic stalks on the GMP chassis, which helped, but then that just removes the first obstacle. Much more clearance had to be created at the base of the A-pillars as the body slips down over the rollcage door bars, and then once we cleared that hurdle, then we had one last challenge. Notice how the exhaust exits the GMP Camaro body.  Well, the good news is that it has to exit the SunStar body in the same place (meaning that the chassis and donor body at least match up favorably), but this required another hole and some clearance on each side, but I think I have reached a plateau.  Here are a couple more progress shots.    The doors don't fit, as the molded in diecast frames for the inner liners interfere with the cage, so another night of grinding and we'll have a look at the entire package. Thanks for all your kind words and encouragement! |

|

|

|

Post by arcticwolf on Sept 28, 2020 9:24:14 GMT -8

I really like this. You're doing in metal what I like to do in plastic. Looking great!

|

|

|

|

Post by Joel_W on Sept 28, 2020 10:54:37 GMT -8

The clean up really looks good. This is turning into one epic build for sure.

Joel

|

|

|

|

Post by Oldtimer on Sept 29, 2020 9:24:21 GMT -8

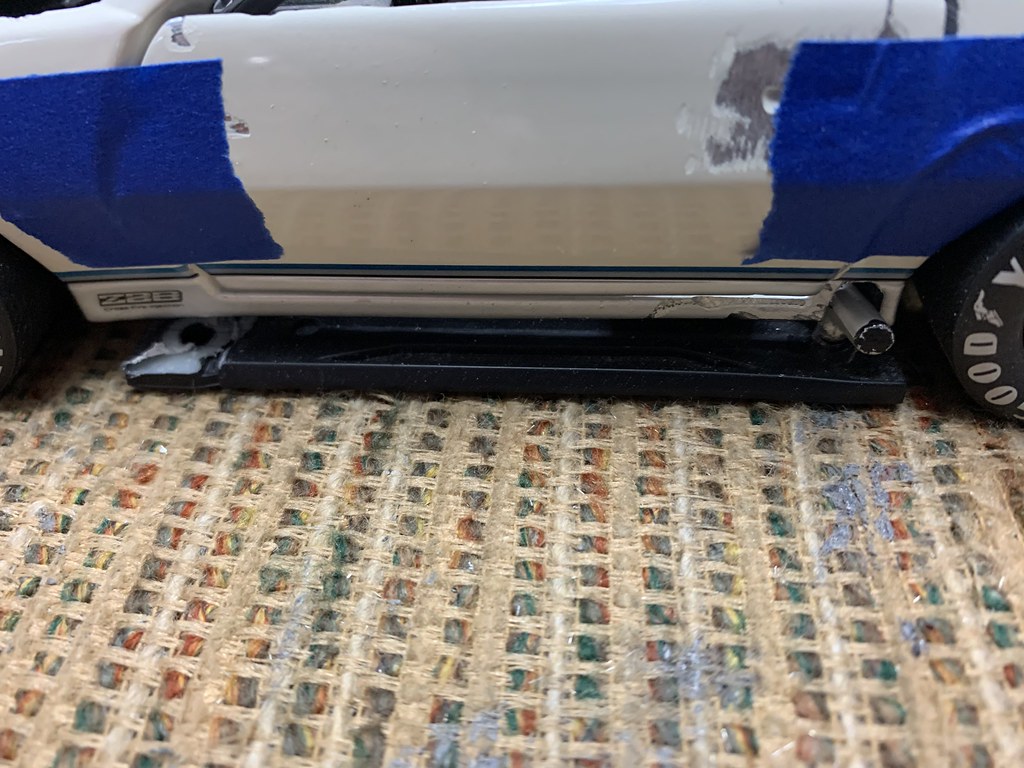

The continuing saga. As you get deeper into one of these blending projects, the level of detail increases, with respect to the accommodations that need to be made to each major component. Got the doors hollowed out, and mounted one onto the body.  One of the first things I need to consider is this major disconnect where the body and floor join along the rocker panel.  I can certainly trim back the floor pan of the GMP chassis (and again violate my own requirement to keep it as intact as practical), but there is still a gap that will need to be filled somehow. Front (and rear) track is too wide, so I need to figure out how to flare the fenders to cover the tops of the tires. I have a choice of several pre-molded flare lips that I will need to test fit.  Will also need to close this gap, at the rear, or at least detail it to where it doesn't simply look like two models squished together.  The dry break comes up short compared to the Sunstar rear window. Thinking about cutting it off, bending some aluminum tubing, and actually having it come out at the molded in fuel filler location on the SunStar body.  |

|

|

|

Post by Joel_W on Sept 30, 2020 15:13:39 GMT -8

Jim,

Every picture has what looks to me as a major problem that isn't going to be easy to fix. Needless to say I'm really looking forward to each fix issue solved.

Joel

|

|

|

|

Post by Oldtimer on Sept 30, 2020 17:47:30 GMT -8

Jim, Every picture has what looks to me as a major problem that isn't going to be easy to fix. Needless to say I'm really looking forward to each fix issue solved. Joel Going to try to pick them off one at a time, simultaneously. Here's how we look at the end of today.  From the front to the back, I'll start with the hood. If you look at one of the earlier pictures, the hood stood up at the base of the windshield. There were some details cast into the underside of the hood that were interfering with the air cleaner and windshield base, so those have been removed.   The donor has T-tops, and of course, our car had a solid roof, so beginning to work on melding them together, and then closing the gaps with body putty.  And, of course, we've got the fuel filler relocated.  I will keep walking around the model, correcting items as I go, knowing full well that frequently a correction will require another one, due to the relationships of pieces changing as you go. |

|

|

|

Post by Oldtimer on Oct 5, 2020 15:21:24 GMT -8

Quick update. Diecast pieces are at the stripper, so I've worked on the T-tops a little. As I was sitting in my shop, it reminded me of building the real one. Sports Car Club of America rules at the time of our build required that the car have a stock roof and windshield (eventually we would add a Lexan windshield when the rules changed). The location of the roof heavily influenced where the rest of the fibreglass body was hung on the chassis. You can see the stock roof in this picture, which includes the front A-pillars.  In order to get our roof located correctly, I borrowed a buddy's IROC Z and drove it down to the shop. We set the two cars side by side and moved the roof around on the cage until it looked right. When then fabricated some mounting tabs and welded it onto the cage tubes. With a realization that the A pillars of the diecast donor body are cast into the body, I thought these pictures, to some degree, represented the roof mounting process we went through back then.   I IAnd then just for fun, I laid on the front windshield and rear glass.   Hoping the stripper calls today and says the body is ready. |

|

|

|

Post by Joel_W on Oct 6, 2020 6:44:07 GMT -8

Jim,

Simply amazing detail work. And please keep those background stories coming as I enjoy them almost as much as your progress on the Camaro.

Just one question. If the SCCA mandated the original windshield, which I'm assuming was safety glass, with all the cars kicking up rocks, pieces of asphalt, etc. just how long did the average one last before replacement was needed from cracks?

Joel

|

|

|

|

Post by Oldtimer on Oct 6, 2020 10:43:08 GMT -8

Jim, Simply amazing detail work. And please keep those background stories coming as I enjoy them almost as much as your progress on the Camaro. Just one question. If the SCCA mandated the original windshield, which I'm assuming was safety glass, with all the cars kicking up rocks, pieces of asphalt, etc. just how long did the average one last before replacement was needed from cracks? Joel I don't remember ever losing a windshield in the three cars that I raced in that were set up that way (my original '69, our C3/Pickett, and the initial runs with the '86). Guess we were either lucky or out front. And I've got more stories, trust me!  |

|